Client testing stud welding machine

June 12,2024

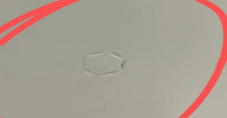

Material deformation pits, damage by external forces, visible depressions after powder coating |  |

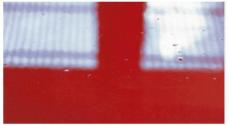

Visible traces after powder coating |  |

Defective notches generated by laser cutting |  |

Squeeze marks generated by bending mold |  |

Visible traces of rivet nuts after finish |  |

Poor flatness of the board, poor straightness of the profile, and overall deformation caused by material defects or processing |  |

Local deformation caused by impact during transportation |  |

The marks formed by uneven polishing of the weld seams |  |

not flat splicing seams with obvious gaps or cracks at the splicing welds |  |

slot holes Increased according to actual needs when designing bending processes |  |

Plastic powder block or impurities that protrude from the surface or clump in the coating |  |

Multiple shrinkage pores with visible depth are generated in the coating |  |

A big block wrinkled surface resembling orange peel on the coating |  |

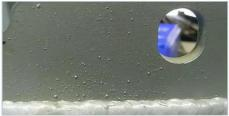

Much bubble protrusions appear on the surface due to poor spraying operation |  |

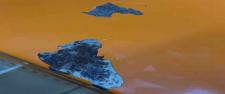

coating peeling off due to poor spraying operation or collision |  |

The partly powder layer is too thin, resulting in a uneven color block after finish and the visible surface of the substrate, usually in the corner or back side |  |

The marks left by the hook shielding during powder coating |  |

Due to excessive and uneven local spraying, there is a concentrated accumulation block after finish |  |

Due to excessive local spraying, thick and concentrated coating blocks are produced in the corners |  |

Due to incomplete cleaning of the production line, there are color spot defects that do not match the color of the product |  |

Traces left on the surface of the product due to incomplete cleaning of oil stains |  |

The difference color than sample or the color card |  |

not smooth surface between the junction of two different colors |  |

Pattern blurring, ghosting, breakage, tilting, deviation, poor adhesion, after screen printing |  |

Welding slag splashed onto the surface of the plate but not removed |  |