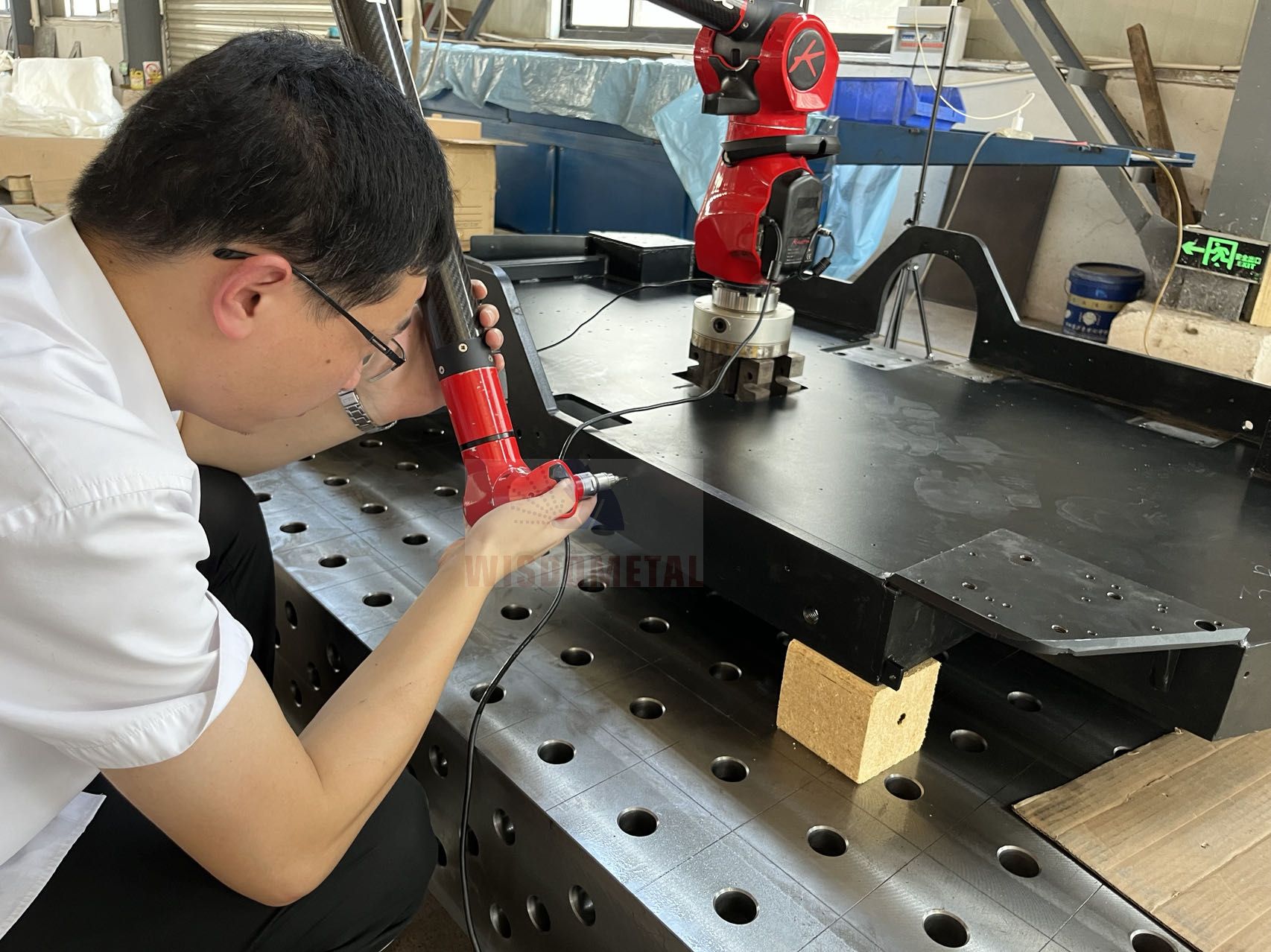

Client testing stud welding machine

June 12,2024

As a professional precision metal manufacturer, we're aware of the importance of quality which is throughout the whole process of material purchasing, manufacturing, inspection, packaging and transportation. We could provide COA/COC and CTQ inspection report for futher needs.

For single planes or flat parts, +/- 0.010” on edge to edge, edge to hole, and hole to hole features; +/- 0.010” on bend to edge/hole features. For multi-planed bent parts, +/- 0.030” for hole to hole/edge, edge to edge, and over-formed parts; +/- 1 degree for bend angles.

– Multiple granite inspection tables

– Full range of precision calibrated micrometers and calipers

– Specialty micrometers for threads, internal measurements and more

– Precision calibrated height gages

– Feeler gauge, MikroTest Coating Thickness Gauge

– Subcontract partners for trilinear coordinates measuring instrument detailed 3rd party inspections

Case #1

Item: Main guide rod of Piezoelectric inkjet printer

Customer: AMSKY

Quality requirement:The surface flatness tolerance<= 0.4mm

Test Result: The surface flatness tolerance 0.2~0.3mm

Case #2

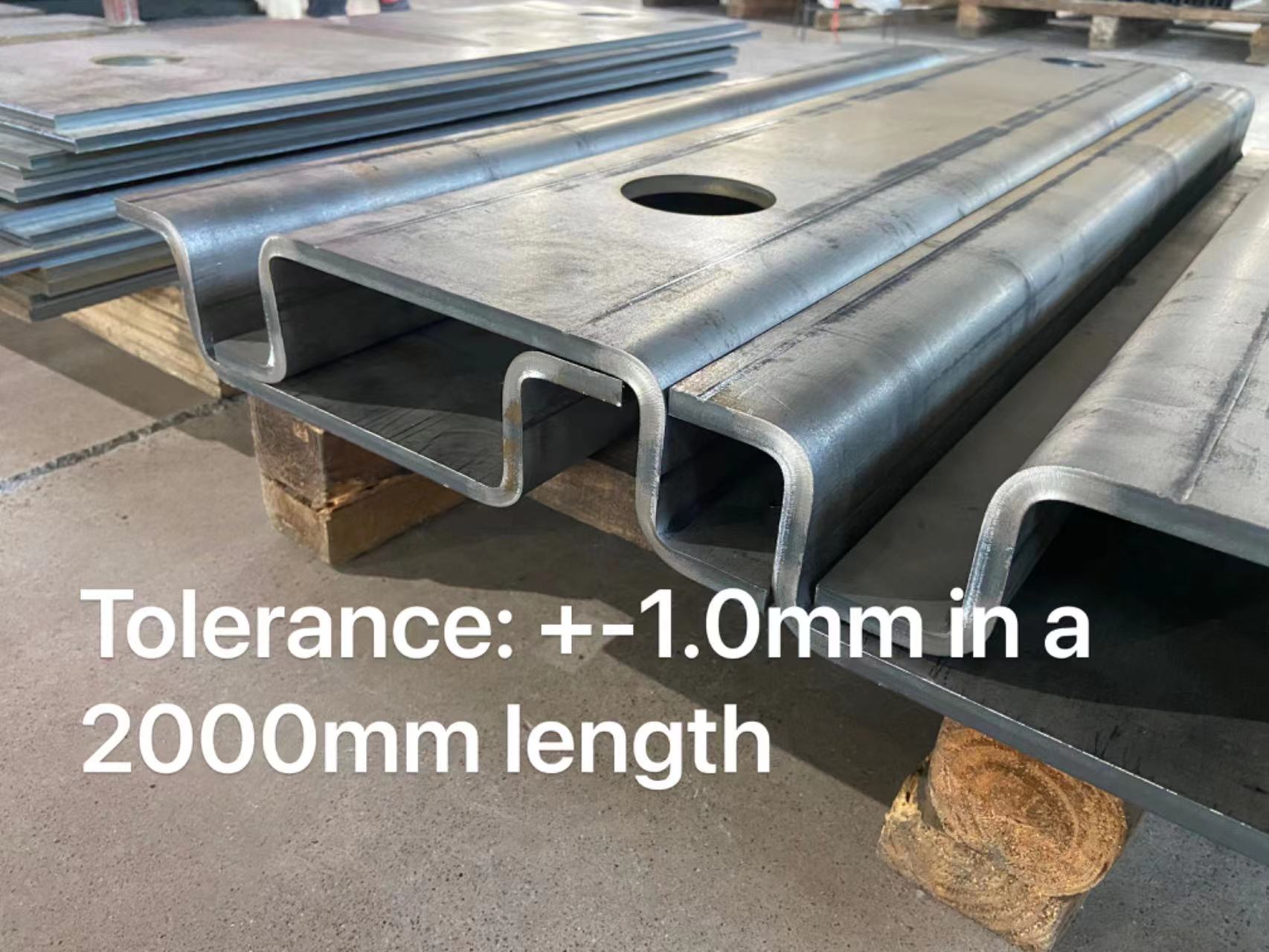

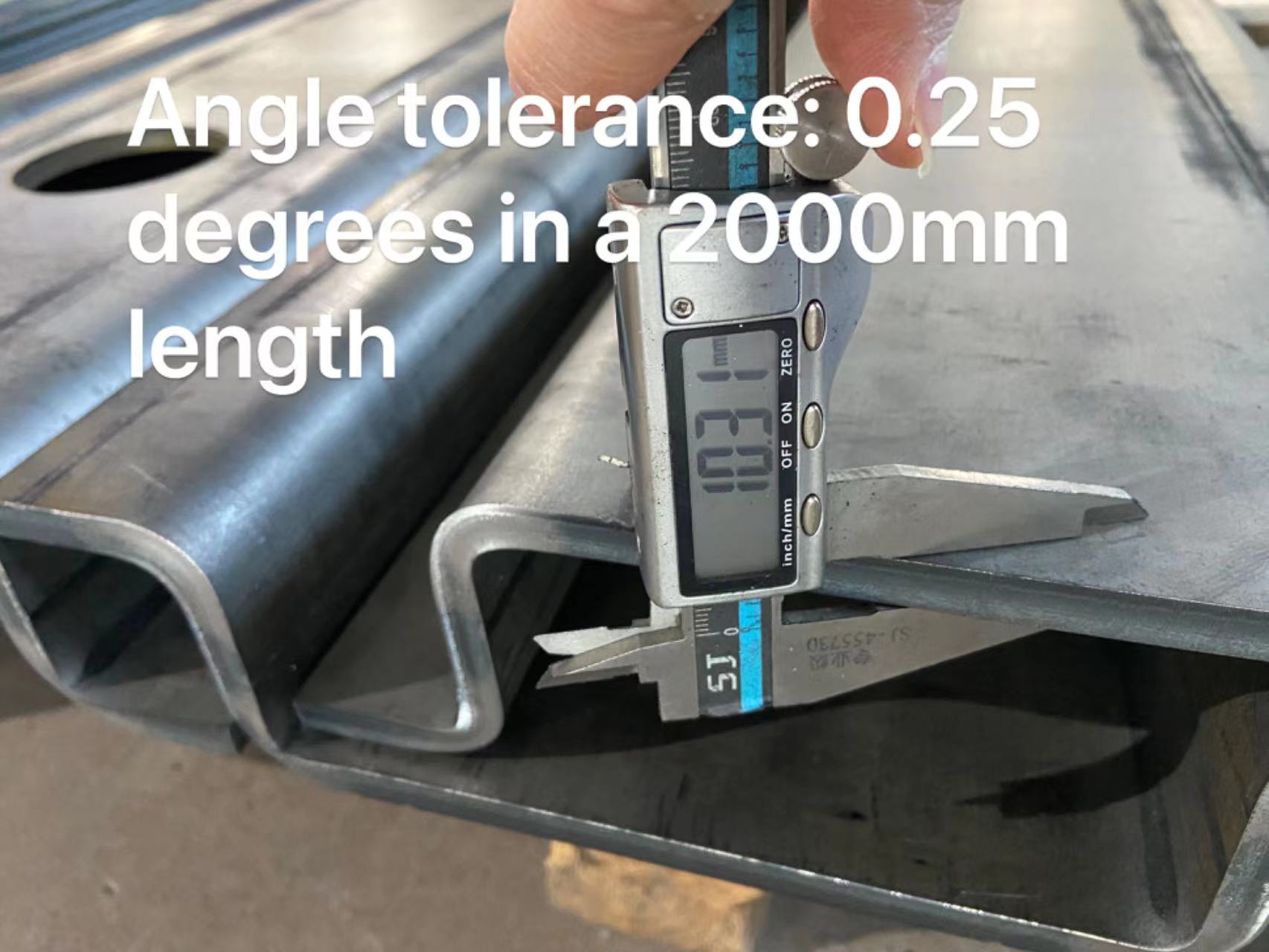

Item: 10mm thickness bracket Of cooling machine

Customer: Dry Coolers Inc

Quality requirement:Dimension Tolerance: +-1.5mm of a max length of 2000mm and10mm thickness; Angle Tolerance:+-0.5 degrees of a max length of 2000mm and 10mm thickness;

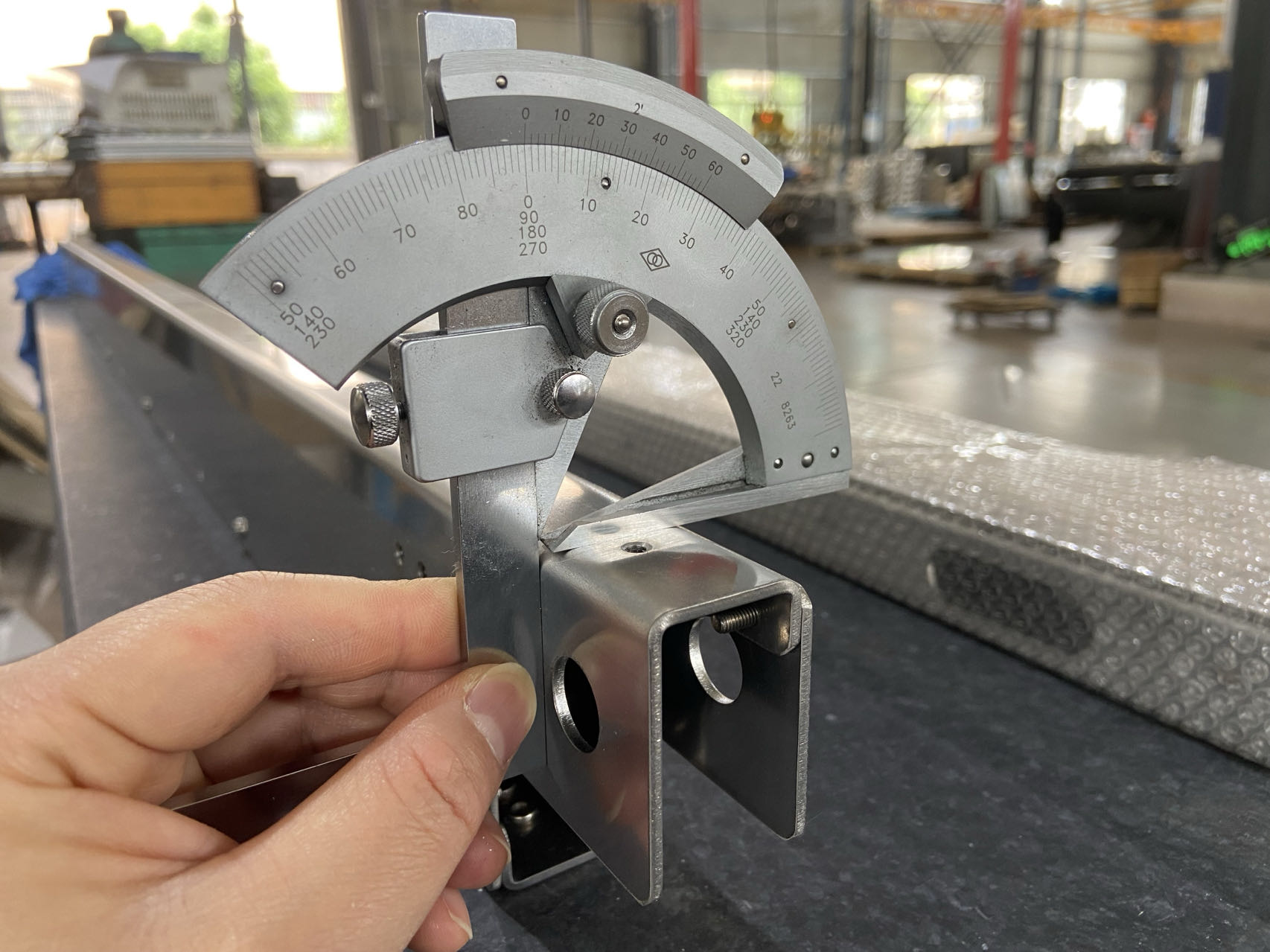

Test Result: Dimension Tolerance: +-1.0mm of a max length of 2000mm and 10mm thickness;Angle Tolerance:+-0.25 degrees of a max length of 2000mm and10mm thickness;

Case #3

Item: 15mm welding base of AMR robot chassis

Customer: Geek+

Quality requirement:Dimension Tolerance: +-1.2mm in each 1000mm; Angle Tolerance:+-0.8 degrees;

Test Result: Dimension Tolerance: +-0.5mm in each 1000mm;Angle Tolerance:+-0.5 degrees;

In order to check the quality management system and document the quality striving of Wisdometal, the management has decided on certification, as well as the associated regular monitoring, according to ISO 9001:2015.

ISO 9001 is a globally recognized standard that defines requirements for effective quality management in a company. Designed to be industry-neutral, it is valid for companies from industry, business and services.

The quality of material cannot always be assessed with the naked eye. A well-known example of this is counterfeit branded clothing that is sold as originals. This is similar with metal, as it is often difficult to see from the outside whether the material meets the requirements. Product names and test seals can also be forged.

For this reason, non-specific factory certificates and specific inspection certificates were introduced. These are always created individually for each of our material orders and archived by us.

We guarantee the use of metals with the highest possible quality standards. We will provice material testing certificate with original steel factory stamps for material we use in your products.

This ensures that you can provide written evidence that high-quality material was used for your sheet metal components, which was delivered to us by our suppliers in accordance with the ordered requirements.

If this factory certificate is required, you can specify this when placing your order for laser cutting.

On the document you will find all information about:

Material description (e.g. alloy, dimensions, weight)

Chemical analysis (percentage of chemical elements)

Mechanical properties (e.g. tensile strength)

We produce high-quality sheet metal parts and it is very important to us to

protect them as best as possible from damage during transport. Our

packaging team ensure that your laser and bent parts reach you without

damage and as sustainably as possible.

We set a series strict standards for our shipping department so that the

parts are packaged appropriately so that no damage occurs during transport,

especially to individual sheet metal parts with particularly sensitive properties.

Our team determines the most appropriate packaging and shipping method

based on size and weight. We fundamentally differentiate between parcel

shipping, pallet shipping and collection from the factory. Hand over order to us,

we will take care the safety packing method for you.