Client testing stud welding machine

June 12,2024

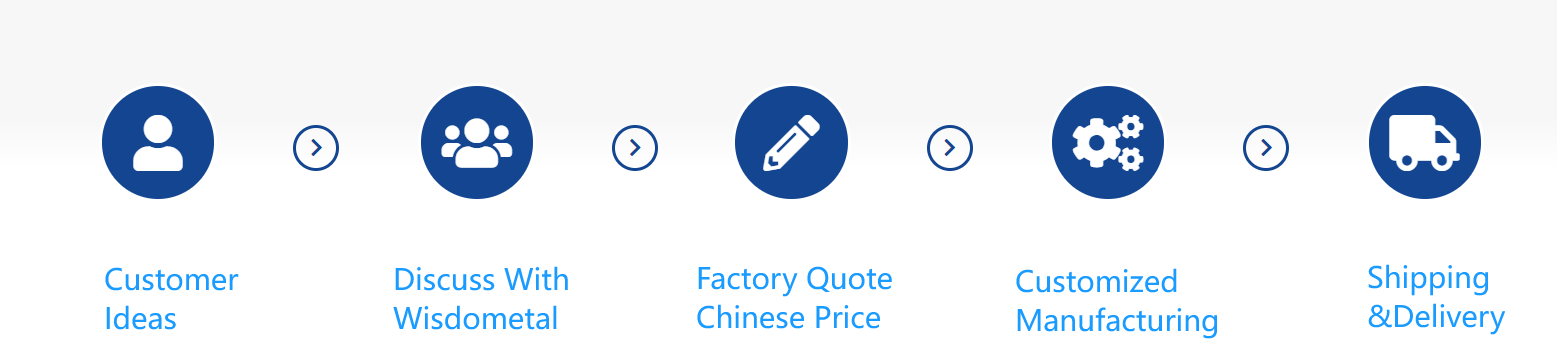

We Make Our Customer`s Ideas To Reality

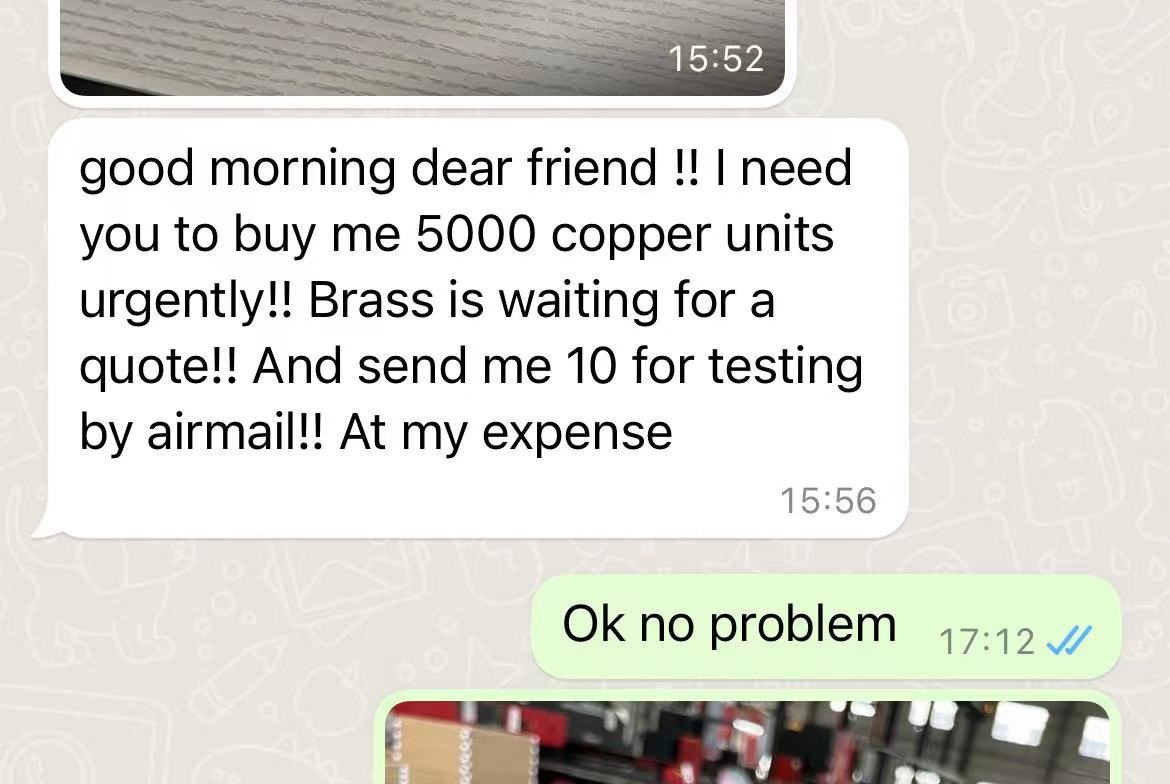

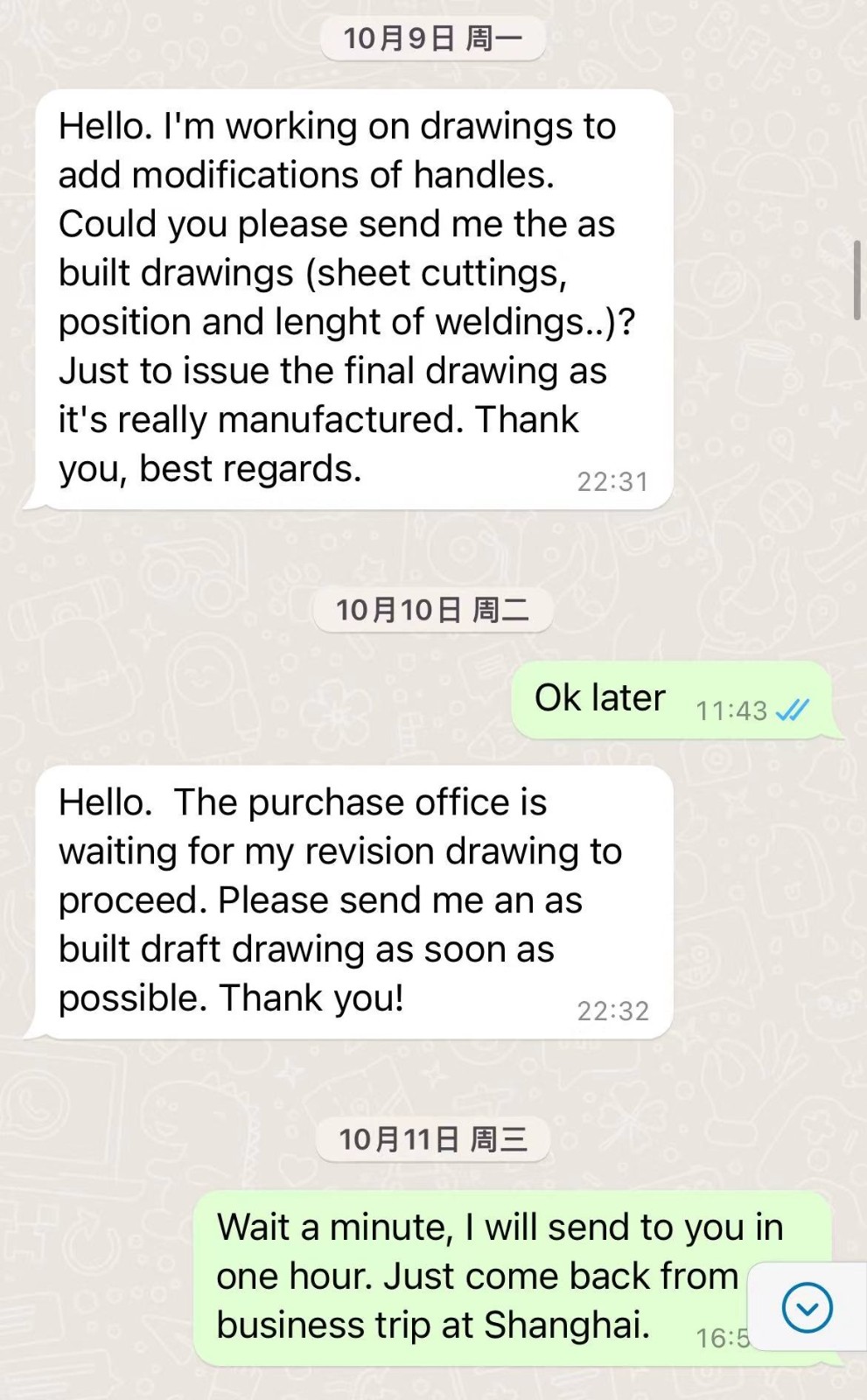

In personal meetings with our customers, our experienced designers find the ideal solutions for implementing sheet metal designs.

If there is already customer data available, we can also input and process all common formats such as: Igs, step, sldprt, dxf, dwg, sat and many more.

We would calculate your sheet metal parts in just a few hours and send back quotation immediately after receive your sheet metal inquiry. You could also send an entire sheet metal assembly files and our team will breaks the assembly down into individual parts and quote them in 24 hours. If you don`t have handy CAD drawings or 3D files currently, send us a sample, we will do the rest for you. If you don`t have a sample, instead you have an idea, talk to us, we will assistant you to design it and will make a prototype in a week.

After you have placed the order, the sheet metal parts will immediately go into production with us. With 30 years of experience in sheet metal processing, you have a strong team in the background that you can rely on.

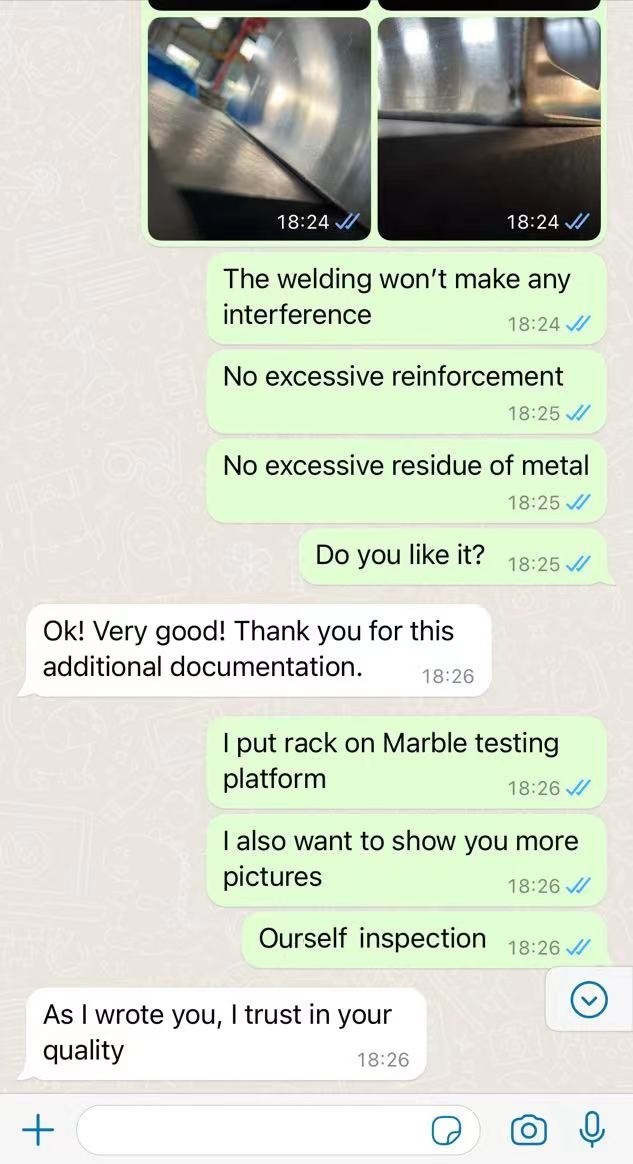

After completing your custom prototype parts, we will send them to you immediately by express. After sample passed your inspection and testing,we could start to produce your sheet metal parts or manufacture your assemblies.

Usually for a mass order, the leadtime will be 30-45 days. After we finished your order, the goods will be shipped to you via a sea shipping company in 15-35 days. For urgent order, we can also ship by air, which is more expensive but you could received it in your local airport in a week.

1.Confirm the prototype with customer before mass production;

2.Able to process draft or drawing of prototype, and review with

Autocad, Solidworksfor fit, function and manufacturability from

concept to sheet metal production technology

3.Capable of designing and producing complete machines based

on customer sales needs, starting from drafts and concepts

4.Reasonable design of packaging for long distance transportation

before production

5.3D fixture design, manufacturing and inspection capabilities

6.Ability to adjust appropriate materials, processes, and tolerances

based on customer`s feedback on product application effects

7.Provide inspection report for each critical part before delivery

8.Provide 8D report and quick response plan to client in case quality

issue happens

We produce high-quality sheet metal parts and it is very important to us to

protect them as best as possible from damage during transport. Our

packaging team ensure that your laser and bent parts reach you without

damage and as sustainably as possible.

We set a series strict standards for our shipping department so that the

parts are packaged appropriately so that no damage occurs during transport,

especially to individual sheet metal parts with particularly sensitive properties.

Our team determines the most appropriate packaging and shipping method

based on size and weight. We fundamentally differentiate between parcel

shipping, pallet shipping and collection from the factory. Hand over order to us,

we will take care the safety packing method for you.

1.The right team with experience inspecting and ensuring compliance with a variety of tolerances and design requirements

2.Record and inspect delivery notes, material testing sheets, and outsourcing business production schedules for our factory and various suppliers

3.Ability to select alternative suppliers based on the quality of outsourced business

4.Coperate with SGS and other third party's in -site inspection if necessary;

5.Have regular maintenance schedule for all measuring tools;

6.Strict controls and checkups are conducted on a regular basis

Convenience

From concept to completion,one-stop turnkey shop

Solutions

We do what others can`t and create innovative solutions to meet schedules, budgets and project goals

Quality

Exceeding your expectation is always a priority at Wisdometal`s ISO 9001:2015 compliant quality program

Safety

Strict safety program and superior record with regular OSHA consultation visits

Confidentiality

We hold high confidentiality clearances with some of the largest companies and work hard to ensure your proprietary information remains yours!

Large Capacity

Large manufacturing spaces, In-house equipment capacity, and project management experience for big projects.

Dedication

Focused project teams ,on time, on budget. PERIOD

Satisfaction

Continuous improvement to make sure you are always happy